Product Type

About Product

Measurement

FFT Analysis is a powerful tool which helps in identifying the causes of vibration using frequency v/s amplitude. For instance, a peak at the running frequency indicates presence of imbalance. Peaks at multiples of running frequency of the rotor indicates misalignment and looseness.

Powerful and fast frequency analysis (FFT based) is provided on an on-screen graphical display. It instantly shows you the various frequency peaks and corresponding magnitudes in a graphical, as well as a tabular format. The tabular report can be instantly printed by connecting to the mini-printer (3064) (standard accessory of the 6090), and the composite report can be saved in its internal storage. There is virtually no limitation on the number of files stored. It offers the option of saving your files in an organized manner under a specific machine name and within it the locations (both user-provided).

Order Analysis is a FFT based analysis tool which gives you a spectrum at a synchronous frequency. You need to connect the reference sensor which senses the running RPM and provides a spectrum upto 8 multiples of rotor RPM.

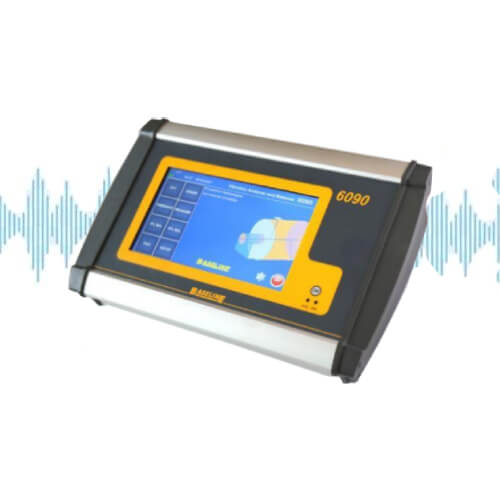

Single and Two Plane Field Balancing, FFT-based frequency analysis, Order Analysis, Time Waveform, Vibration Measurement, and monitoring in a single, compact, and portable instrument.

True RMS measurements as per ISO 2372 and IS 11724

Large 7" Colour LCD touch-screen interface.

Automatic peak finding and tabular presentation of data.

Virtually infinite internal storage of balancing, FFT analysis and vibration monitoring reports.

Monitoring and saving records of vibration over specified time-periods ranging from 1 sec to several minutes.

Single-plane and Two-plane dynamic field balancing vector calculations built-in.

Printer (3064) provided as a standard accessory for printing balancing/analysis/vibration data.

Two independent channels for Accelerometer sensors.

Rechargeable maintenance- Free battery.

Lightweight and portable, fits into a briefcase.

Two- plane and single- plane dynamic balancing can be performed in- situ with the 6090. it has all the required vector calculation algorithms built-into its program. Thus the operator is freed from the task of determining the weights by calculations or hit-and-try methods, resulting in vastly improved, quick and accurate results.

It is possible to resolve vector results into components (good for bladed rotors), as also have the option of leaving the trial mass intact. The trial mass can be fed in, and result is shown in the same units.

The unit is supplied as a complete kit with one sensor, lead, infra- red reference sensor and magnetic mounting stand as standard. Those requiring 2 sensor for 2 plane balancing can be order an extra sensor.

Quality checking of rotating equipment as an QC check.

Vibration troubleshooting based on FFT analysis

Continuous Vibration Monitoring at periodic intervals.

Order Analysis and Time Waveform display of vibration signal.

Condition monitoring of rotating machines.

In- position 1-plane and 2-plane dynamic balancing with inbuilt computation algorithms.

Conventional and nuclear power plants.

Air- conditioning plants.

Oil industry- prospecting and refining.

Packaging Film Manufacturers

Automobile and others using CNC machines.

OEM manufacturers of motors, pumps, blowers, impellers, and industrial fans.

Process plants - Cement, Petrochemicals, Chemicals, Steel, Glass, Rayon and Yarn.

The unit runs of rechargeable batteries & has no moving parts.

It employs the latest surface-mount technology for ensuring a lightweight, compact and reliable design.

NPL traceable calibration is furnished with each unit.

| Inputs | Two inputs for vibration sensors (accelerometers), one for optical reference sensor (RPM Sensor). |

| Measurement Modes | Acceleration (RMS- m/sec2); Velocity (RMS-mm/sec); Displacement (PK-Pk microns) |

| Measurement Ranges | Auto-ranging. |

| Acceleration | 0-199 m/sec2 True RMS |

| Velocity | 0-199 mm/sec True RMS |

| Displacement | 0-4000 microns Pk-Pk (subject to vel/accel limits as above) |

| Frequency Range | 0-4000 microns Pk-Pk (subject to vel/accel limits as above) |

| Display | 7" Colour LCD with Touch Controls |

| Frequency Analysis | FFT analysis of vibration upto 1kHz and graph display

on LCD screen. Peaks Report can be stored in the unit and printed with the supplied printer 3064, or transferred to the PC via USB converter. |

| Weighting Window | Rectangular, Hanning, Hamming |

| Peaks detection | Tabular results of peaks observed are shown on the screen. |

| Zoom | 4X for low frequencies upto 256 Hz |

| Order Analysis | Order analysis to track the rotor rpm and show synchronous peak and peaks of multiples of the running RPM. |

| Time Waveform | Time waveform displayed on screen. |

| Field-Balancing | Single-Plane Balancing Two-Plane Balancing Easy to follow procedure with prompting of steps. Balancing Report can be stored in the unit and printed with the supplied printer 3064, or transferred to the PC via the USB converter. |

| Printer | 3064 Thermal Printer with 2" paper roll with RS232 Port |

| PC Communication | Reports can be transferred through USB converter to the computer. |

| Dimensions | Instrument: (6090): 290 (L) x 185 (W) x 70 (H) mm. Carrying Case: 465 (L) X 360 (W) X 140 (H) mm (Supplied fitted in a foam-lined case) |

| Weight | 1.6 Kg approx. without carrying case. |

| Shipping Weight | 6.35 Kg approx. with carrying case and all standard accessories. |

| Battery | 6.35 Kg approx. with carrying case and all standard accessories. |

| Battery charger | Separately supplied as standard accessory |

| Temperature range | 0-45 Deg C upto 90% humidity (non-condensing). |

| Standard Accessories | 1. Sensor with 3m lead, 1. Magnetic base, 1. Reference

sensor, 1. Magnetic stand, 1. Battery charger, 1. USB

Converter, 1. Briefcase type carrying case, 1. Thermal

Printer 3064 and 1 Operation Manual NOTE: 2 Plane balancing requires 2 sensors. |

| Optional Accessories | Sensor for Two Pane Balancing, Printer Rolls, Touch Probe, 360 Degree Protractor |