About Product

VLSAT is available for

Android® tablets

Microsoft Windows®

iOS® for iPad

Improve asset availability & uptime through precision alignment.

Reduce unnecessary costs associated with unplanned failures & premature wear

Reduce your energy Consumption.

Wireless Bluetooth® Communication for Safety

More efficient, and faster than dial indicators

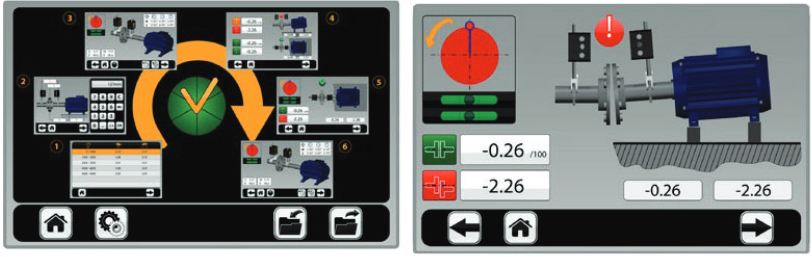

5-Steps-Simple™ alignment Process

.png)

Degree of protection IP65

Operating time 20 Hours

Operating temperature: 14oF to 140oF (-10oC to +60oC)

Detector type Digital CCD detector 30mm

Measurement distance Up to 10m

The VLSAT sensor units use the latest digital, and Bluetooth® data processing technology. Eliminating pre-alignment and minimizing setup time is intrinsically engineered into the VLSAT through the utilization of our exclusive 30mm CCD-detectors. This provides you with exact and stable measurement results and enables the system to be more interference-immune from the external factors (stray light, vibration, thermal growth etc.). Thanks to the compact and durable aluminum case of the sensor units, you can work in the most confined and harsh environments.

HORIZONTAL ALIGNMENT

THERMAL GROWTH CORRECTION

Easily and accurately compensate for thermal growth using the VLSAT thermal growth correction module.

CLOCK METHOD

This alignment method requires collecting a measurement points at any 3 of the 4 pre-defined clock positions. (3-6-9-12 o’clock).

VERTICAL ALIGNMENT

Vertical shafts alignment is carried out by moving the machine flange/coupling until the axes are coaxial enough to stay in the assigned limits.

Note! Coupled and Uncoupled Shaft.

SOFT FOOT

Before any alignment soft foot should be addressed.

MACHINE TRAIN

This alignment method is for aligning multiple components across several couplings. Coming soon

POINT METHOD

This alignment method allows you to begin collecting measurement points at any angle of shaft rotation and automatically collects a measurement anytime you stop rotation. Minimum of 40 degrees of rotation is required.

CUT ANGLE

This alignment method is best used when 180 degrees of shaft rotation is not possible. The minimum required shaft rotation is 40 degrees. The more rotation, the better and more precise the alignment.

Zone Expansion

Unique technology that reduces the efffects of high vibration and competing light sources on precision alignment.

Sensor Unit Readings

The display shows data received directly from thesensor units (position of the laser beam on the sensor and inclinometer).

Multiple Sets Of Feet (Coming Soon)

Allows the user to align machines with more than two sets of feet.

Smart Measurement Value Filter

Statistically analyzesmeasurement values and normalizes data collected utilizing a 95% confidence interval to insure the data points used to calculate alignment corrections are representative of the entire dataset. Best used in high vibration areas. (coming soon).

Choose your system of measurement

Touch the Icon “Sensor units search”. After initial use the sensor units the software will automatically connect to the applicable heads.

SwitchIT™ Function (coming soon)

Before any alignment soft foot should be addressed.

Continue Alignment

Start a new alignment, redo a previously completed alignment, or save at any step in the alignment process and go back to finish anytime.

Saving Data

Saves your alignment job and all respective measurements, photos, and details to the database for easy access later.

Report Creation

Generates a PDF report.

Add Photo

Allows the user to take a photo with their devices internal camera of the machine being aligned for reporting purposes.

Send The Reports

When configured allows the user to easily send reports via their email client / service.

Send To USB

Allows the user to export alignment job data to USB for use with other VIBRO-LASER systems..

Add Notes

Allows the user to manually enter notes related to the alignment job or about the machine being aligned. This tool is great for general observations.

1. Display unit (1pcs IF INCLUDED).

2. Sensor unit S (1pcs).

3. Sensor unit M (1pcs)

4. Complete v-bracket (2pcs).

5. Carring bag (1pcs).

6. Chain with lock (2pcs).

7. Display unit adapter (1pcs).

8. Sensor units adapter (1pcs).

9. USB cable (2pcs)..

10. Tape measure (1pcs).

Tablet- 8 inch

Tablet- 10 inch