Infrared Thermography Services is one of the more sophisticated NDT methods recently applied in detecting heat generating anomalies and has become a major player in achieving reliability and quality for both mechanical and electrical equipment through the implementation of Equipment Preventive Maintenance Programs. Heat is detected by an infrared camera. The camera translates heat to a visual image normally called a thermograph.

Condition Based Maintenance Infrared thermography is used for condition monitoring, CM, to optimize maintenance and keep production running smoothly and safely, at the lowest possible cost.

It captures as a temperature distribution on a surface, and it can display as a visible information. Temperature can be measured from a distance without contacting an object.

Temperature can be measured in real time.

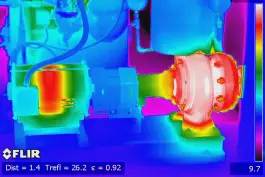

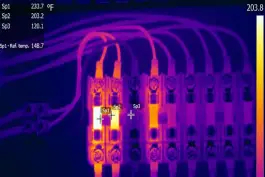

Electrical infrared inspections find hot spots caused by defects in connections and components. Increased resistance and heat are the primary reasons most electrical components fail. Infrared cameras detect this heat. Infrared scanning is used to inspect electrical equipment because excess heat is usually the first sign of trouble. Loose connections, imbalanced and/or overloaded circuits, defective breakers, damaged switches, faulty fuses, and material defects all lead to equipment failure and these are detectable by an infrared inspection.

Electrical infrared inspections are typically conducted on an annual basis as part of a regular preventive maintenance program. The infrared electrical testing allows for inspection of a large amount of electrical equipment in a short time as opposed to the alternative method of physically inspecting and tightening electrical components. The electrical infrared inspection locates faulty electrical items not generally found during a physical inspection.

Electrical infrared inspections locate problems before they lead to an unscheduled outage, equipment damage or a fire. Today's facilities engineers are avoiding costly expenses every year with infrared electrical surveys. An infrared inspection or survey can substantially improve profitability and reduce your operating, testing and maintenance costs by offering the following benefits:

Quickly pinpoints electrical systems problems

Prevents catastrophic and costly system failures

Reduces downtime and electrical equipment damage

Drastically improves preventive maintenance efficiency

Can be tested under load to avoid costly system shutdowns

Allows engineers and facility managers to establish repair priorities

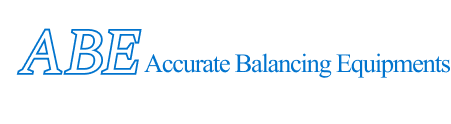

Inspecting mechanical equipment with infrared thermography covers a wide variety of systems, everything from motors, rotating equipment, steam traps, refractory, and tank levels and more. Most of these inspections de-emphasize taking absolute temperature measurements and instead concentrate on comparing overall thermal patterns to understand the asset's health.

Baseline inspections, where a thermographer captures an overall “thermal map” of a particular equipment type, is one of the more valuable uses of the technology, as subsequent inspections are then compared to the original “map” to detail any changes that may have occurred over time. The examples in this article represent only a few of the many areas where IR is utilized for inspecting mechanical equipment in an industrial facility.

Inspecting bearings is another useful application for infrared thermography. Abnormal friction within a bearing, generating heat, causes the bearing's surface temperature to rise. This thermal signature, when detected, is an indication of a potential bearing problem, anything from under-lubrication, over-lubrication, poor maintenance or simply a bad bearing. Infrared is especially helpful for inspecting low-speed equipment, including overhead conveyors or idlers, quickly and easily.

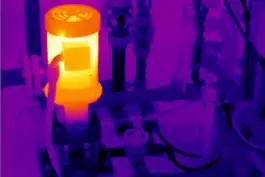

Thermography is also used to monitor temperatures on high-temperature refractory insulation such as a rotating kiln, furnace or boiler. Thermal patterns detected in these cases can be used to monitor the condition of the insulation or even calculate the thickness of the remaining refractory. This type of monitoring is invaluable as it facilitates planned maintenance outages and repair of a problem area vs. a catastrophic, and expensive, unplanned failure.

Real-time output

Infrared cameras offer great mobility

Requires no contact with components or machines

Can obtain data on large surface areas at one time

Easy-to-read visual images

No downtime or production interruptions for testing

Data can be uploaded to software for further analysis

The applications of thermography that have been discovered over the years are numerous and divers. The most common applications we intended in this paper that is condition monitoring in mechanical and electrical equipments electrical power utilities.

Blower

Motor

Fuse units

Turbines

MCC & PCC panel

Switchgears

DC power systems (SMPS)

Cable junction boxes

Change over switches

Motor junction box terminal

Main Breaker/isolator Switches

UPS / Inverter distribution circuits terminals

Pumps

Gearbox

Compressor

Bearings

Pipe leakage

Switchyards

Refractories

Capacitors/ Insulators

Distribution panels/boxes

Main Electrical panels

Transformer / DG Alternator cable junction box

Infrared thermography is a highly recommended preventive maintenance tool in nearly all industries. You won't find another tool that gives you such accurate, real-time data without disrupting the process flow from shutting down your systems. Working infrared thermography into your regularly

| Key Equipment | Conditions Found |

| Electrical Equipment | |

| Electrical Distribution Equipment | Loose connections or poor contacts, unbalanced loads, overloading, overheating. |

| Motors | Overheated bearings, unbalanced loads, overheating /overloading, blocked cooling passages. |

| Boilers and Steam Systems | |

| Boilers | Refractory /insulation breakdown, hot gas leaks. |

| Steam Systems | Valve or joint leakage, insulation effectiveness, underground system leakage, restricted or blocked condensate return lines. |

| Steam Traps | Trap malfunction, backup from malfunctioning downstream of the trap. |

| Mechanical Equipment | |

| Internal Combustion Engines | Blocked radiator tubes and oil coolers. |

| Refrigeration Systems | Air leaks, clogged condenser /heat exchanger tubes. |

| Pumps, Compressors, Fans and Blowers | Overheated bearings, high discharge temperatures, high oil temperatures, broken or defective valves. |

| Kilns | Insulation breakdown, high bearing temperatures, high gear temperatures. |

| Other Applications | |

| Process Industry Dryer Rolls | Condensate buildup, high bearing temperatures. |

| Storage Tanks | Determination of liquid levels, inadequate insulation. |

| Ovens and Furnaces | Insulation breakdown. |